STEEL MELT SHOP

Eco-friendly Steelmaking:

Reducing CO2 Emissions with

Electric Arc Furnaces (EAF)

using scrap as input

1. Steel Melting

35 Ton Ultra High Power ELECTRIC ARC FURNACE

- Automatic Ferro alloy feeding system

- 35 Ton Ultra High Power furnace

- Capable of continuous feeding of DRI, Lime & Coke.

- EBT for Slag Free Tapping help us for production of clean Steel

- The use of EAFs allows us to make steel from almost 100% scrap metal feedstock. This greatly reduces the energy required to make steel when compared with primary steelmaking from ores.

Electric Arc Furnace(EAF) steelmaking using scrap as input results in lower CO2 emissions per ton of steel produced, which is significantly lower than the conventional production route via blast furnaces and EAF with Pig Iron / DRI.

2. Secondary Refining

35 Ton Ladle Refining Furnance (LRF)

- Equipped with Automatic Ferro Alloy Feeding system

- Provision for second LRF

VACUUM DEGASSING (V.D.)

- Vacuum Degassing unit – Mechanical Pumping System supplied by M/s. Edward Mech. Pumps, U.K.

- Help us with the production of lower gas content & cleaner steel.

Cored Wire Feeding

- Cored Wire feeding at VD station helps in fine adjustment of “Ca” and in modification of inclusions & “S” content control as per customer requirement.

- It also facilitates the deep injection of additives into the steel without excessive ingress of air/oxygen.

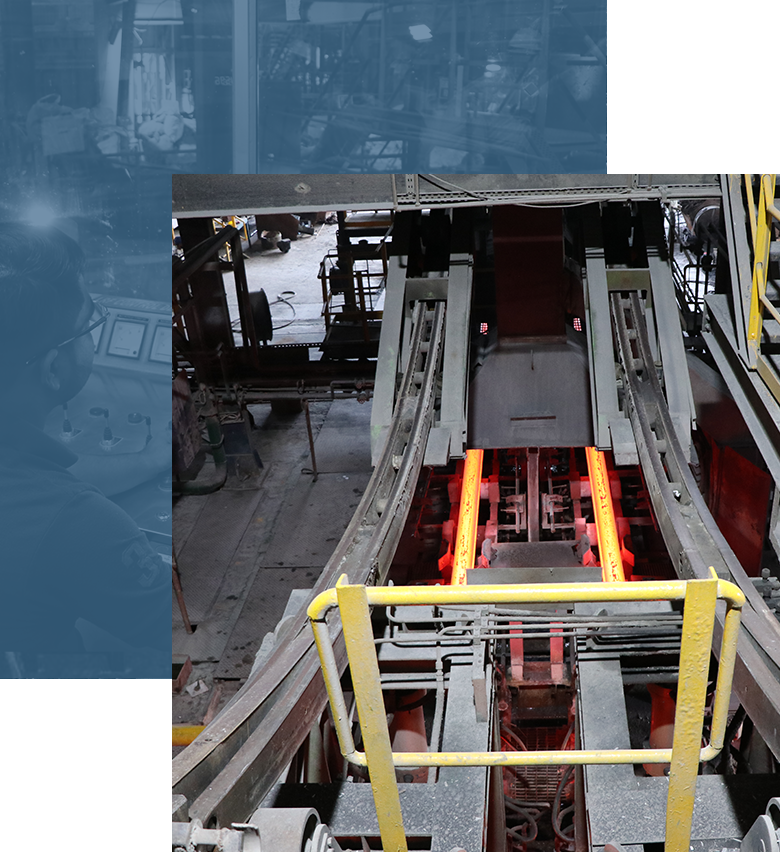

3. Continuous Casting

2 STRAND CONTINUOUS CASTING MACHINE (CCM)

- Multi radius machine

- Automatic Mould Level Controller (AMLC) from SERT France & Berthold Germany.

- Moulds EMS supplied by ROTELEC France.

- Equipped with Hydraulic Oscillator for better quality

- Japanese Copper Moulds from Shinko Japan

- Rigid Dummy bar.

- PLC controlled Casting (Cooling and Oscillation parameters) Auto curling Torch.

- Pit Cooling-100t capacity for sensitive grades.